By Melanie Petrucci, Senior Community Reporter

Photo/submitted

Shrewsbury – When Shrewsbury resident and 3D printing enthusiast John Petrangelo learned of the need for face shields and masks for healthcare workers in the fight against COVID-19, he wanted to help.

Petrangelo is also a mentor to the Shrewsbury High School Robotics Team 467 and enlisted their help in the form of the use of the team’s 3D printer to supplement the output of his own machine.

“I’m a member of several 3D printing groups on Facebook and for weeks and weeks now people have been talking about wanting to print face shields and face masks,” he explained. “A lot of the information was ambiguous – Was it safe? Is it the right thing to do? But then I saw a post from a local nurse from Saint Vincent Hospital in Worcester asking for people to step up and print materials.”

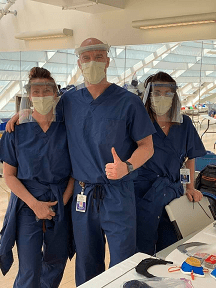

Jacquie Brosnihan, a registered nurse in the operating room at Saint Vincent Hospital, has pulled together a network of people in the area who have answered the call to help.

“She comes by once a week to pick up a box of whatever I’ve been printed for the week,” he said.

“I sent out an SOS call to the 3D Facebook groups asking for help because our N95 masks are in an extreme situation so we were trying to make things last as much as we could,” Brosnihan notes. “The 3D community stepped up in exemplary fashion and committed to helping us so we have enough 3D masks and face shields to provide for at least 50 percent of the hospital staff. It’s an extraordinary effort.”

Petrangelo shared that although he isn’t making complete masks or face shields, he is making the hard shell pieces and the hard respirator portion of the masks. The nurses then do the assembly by adding foam to the part that goes on the face to get a tight fit, adding filters and then the elastic straps to hold them in place.

So far he has donated about 190 masks and 64 face shields that are already in use and he has about 20 more masks and 36 face shields ready for pick-up.

“I’ve had the printers running probably about 16 to 18 hours a day for about four weeks,” Petrangelo said. “My son Nathan helps manage the printers with me.”

Nathan, an alumnus of Team 467, is a sophomore at Rochester Institute of Technology and is at home due to the pandemic.

One of the challenges Petrangelo has faced is getting the filament (plastic for printing), which is really hard to find right now; it’s largely sold out everywhere. Luckily he was able to order some recently, but it can be pricey.

“The robotics team also gave me about three kilograms of plastic to print with,” he noted.

Brosnihan shared that the 3D-printed masks and shields will last and can be used again in the event of another pandemic.

“The guys have done a phenomenal job,” she said. “Their efforts are contributing greatly to morale – the nurses feel like the community is behind them.”

Photo/courtesy Jacquie Brosnihan.